Eurocell, the Anglo-Korean next-generation battery company, has confirmed that it is in advanced discussions to build its first European gigafactory in the Netherlands, supplying battery cells to the energy storage and e-mobility ecosystem across the continent.

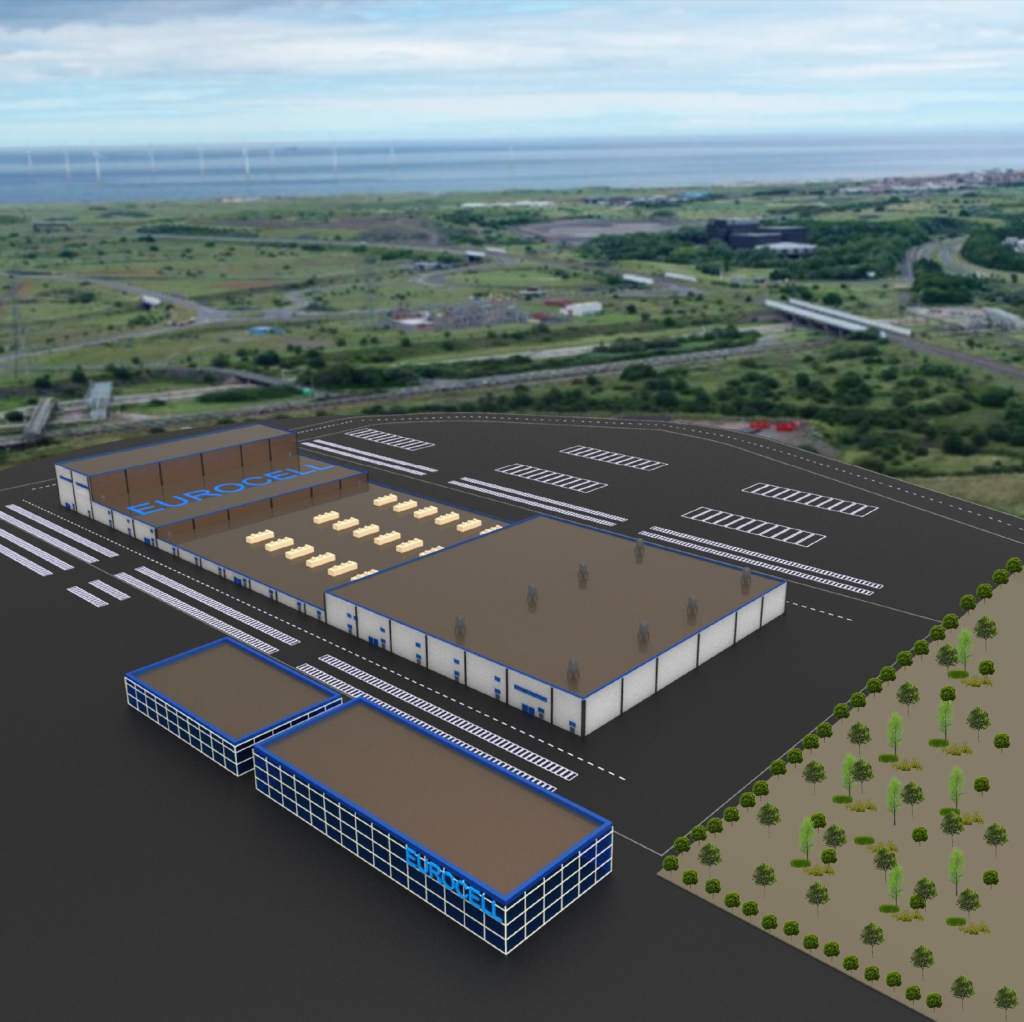

The Worcester-based company intends to construct its new gigafactory in two phases reaching full capacity as early as 2025. The first phase will produce advanced battery cells at scale by early 2023 for existing European customers. The second, potentially on the same site, will be capable of producing more than 40 million cells per year by 2025.

The battery manufacturer claims it uses “verified and proven technology” developed by world-class South Korean developers, delivering higher performance than conventional lithium-ion batteries. Eurocell notes that they are safer, faster charging and discharging, longer lasting, and are able to operate in more extreme temperature conditions. As such they are ideally suited for all applications, including residential and distributed storage, charging infrastructure, automotive and mobility, and auxiliary power systems.

Representing an initial investment of $800m – rising to $2bn by 2028 to support the fast-growing Energy Storage market in Europe – the gigafactory will create “hundreds” of direct and indirect jobs, transferring vital skills from Korean battery experts, in addition to boosting the economy in this strategic sector crucial to achieving the net-zero ambitions of the Netherlands and Europe.

“In its Climate Policy, the Netherlands outlines its ambition to lead Europe in the fight against global warming with a comprehensive strategy to reduce emissions across industries,” noted Nick Clay, the chief commercial officer of Eurocell EMEA.

“As we enter the final stages of discussions, we are confident that we will be able to confirm the exact location of our first European Gigafactory in the near future.”

Eurocell’s batteries, developed in Korea, also have a considerable technical advantage, lasting over ten times longer than conventional lithium-ion cells, making them far more sustainable, with no ‘end of life’ issues, and perfect for ESS applications given it is also 100% safe, according to the battery manufacturer.

Eurocell EMEA is backed by its South Korean partners with decades of experience in electro-chemistry, making batteries at a mass scale, and building gigafactories. It has ambitious expansion plans which have been strengthened by the number of competitive opportunities available in mainland Europe identified during its search for the first phase of its project.

The battery maker has said that it will produce ‘production ready’ technologies in just 12 months, far faster than other gigafactories, using its proven battery product, which is verified and validated for scaled-up manufacturing.