Ionetic has launched a state-of-the-art EV battery pack design platform, stating the new technology can cut the development cost and time for automotive manufacturers.

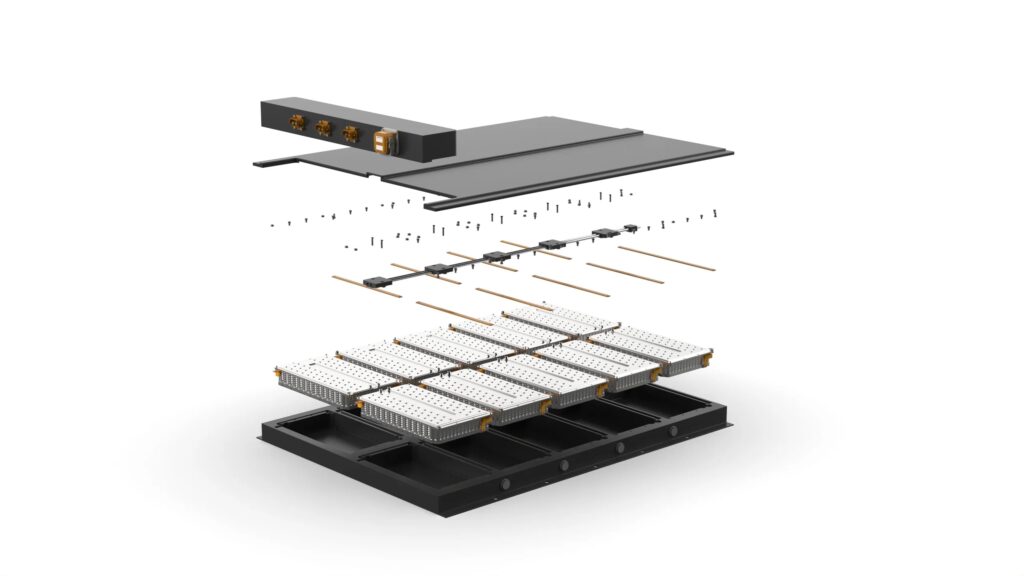

The UK start-up, which specialises in EV battery pack technology, said the new technology can boost energy density by 30% and increase utilisation of pack volume by up to 120%, compared to existing off-the-shelf solutions. The platform can also produce a battery pack design in days and reduce the costs of getting from requirements to mass manufacture by over 90% for automotive OEMs, the company said.

Ionetic is planning to open its first UK-based battery manufacturing facility next year, which will enable it to begin pilot production of its own battery pack designs.

Producing a high-performance and safe battery pack solution has traditionally been expensive and time-consuming for many automotive companies. However, the company says its platform has the ability to automatically generate designs according to a series of fully adjustable parameters, while offering a vertically integrated solution to battery pack production, which includes homologation and mass manufacture.

According to Ionetic, automotive companies need to consider requirements, system design, homologation, embedded control, manufacturing options, and vehicle integration, to name a few. These stages are often done by different companies, which can lead to a costly, fragmented process. The start-up said it facilitates all these stages by simplifying the process and reducing the cost for EV OEMs.

“We’re currently focusing on niche automotive companies in the UK and Europe,” CEO and Co-Founder James Eaton said, referring to companies that typically make fewer than 10,000 vehicles per year. According to Eaton, such companies often don’t meet the minimum order quantities of large global battery pack suppliers, or can’t meet their high design fees.

Eaton said trucks, buses, construction vehicles, service vehicles and emergency vehicles all need to electrify in the next decade. The company is also in talks with iconic car brands and sports car manufacturers.

Gigafactories are mainly catering for mass-produced cars, Eaton said. There’s a risk that some of these niche, historic car brands might not survive electrification unless their specific needs are met, he added.