Drive System Design (DSD) will present an in-depth study showing that, under certain conditions, an induction machine can be superior to its permanent magnet equivalent for motor topology, at The Battery Show & EV Tech Digital Days.

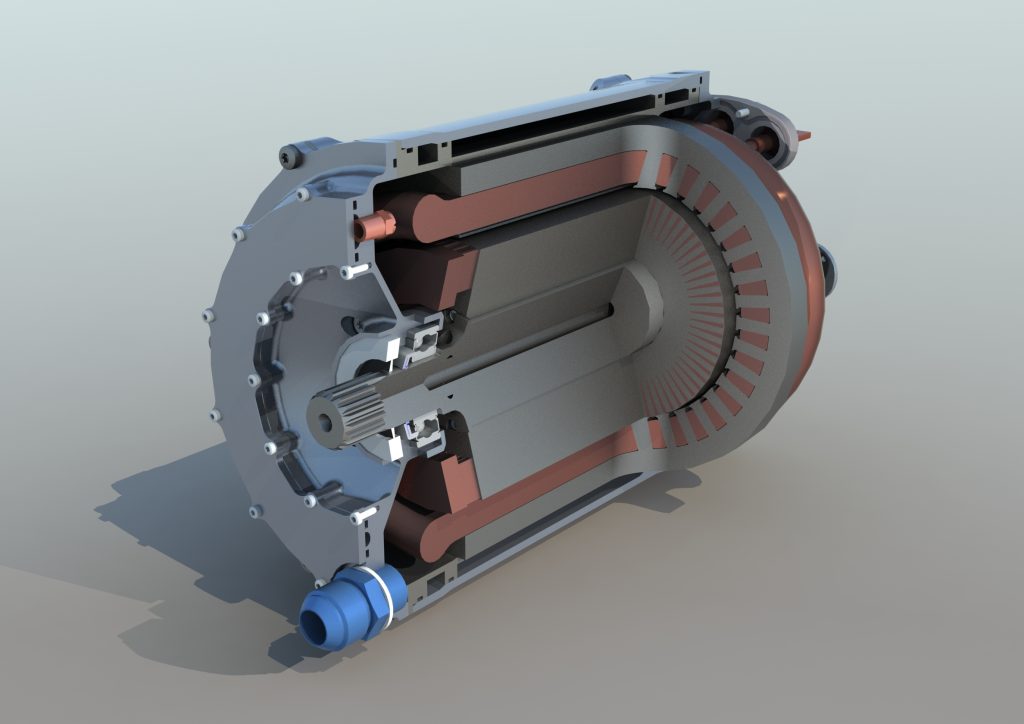

Paul Sims, Chief Technical Specialist at DSD, will detail the work carried out to successfully achieve a high specific output from an induction machine that supports its use as a primary traction device.

One of the key elements in DSD’s approach was the use of its in-house concept architecture selection tool, ePOP (electrified Powetrain Optimisation Process), to allow unprecedented insight into multiple powertrain configurations, potential trade-offs and areas needing development. This tool indicated that high specific performance induction machines have the potential to achieve the required vehicle performance and efficiency targets.

This could be a game changer for the industry as the accepted view is that permanent magnet machines are more efficient and more power dense than induction machines. However, the demand for rare earth materials, which are central to achieving high power density, is rapidly growing, causing raw material price fluctuations that can completely erode typical automotive profit margins. An induction machine doesn’t require the same quantity of rare materials.

Sims’ paper, entitled Induction Machines for Electric Drive Systems – Reducing Reliance on Rare Earth Magnets, summarises the technical challenges faced and explains the potential energy benefit of induction machine topology when applied to traction systems. The presentation is scheduled for November 12th and if you want to find out more about the event, please visit www.thebatteryshow.com.