In a move towards a greener future, Volvo Cars has unveiled its latest offering, the Volvo EX30. As you would expect with Volvo, this small, fully electric SUV has been designed to be safe and comfortable – but also to have a significantly smaller carbon footprint than any previous Volvo model. Volvo says that this shows its strong commitment to reducing emissions throughout the production and lifecycle of their vehicles. The EX30 forms part of a drive by Volvo to cut its overall CO2 emissions per car by 40 percent between 2018 and 2025.

The Volvo EX30 has undergone extensive measures to ensure its environmental impact is minimised. Through a comprehensive assessment, Volvo has managed to reduce the total carbon footprint of the vehicle to below 30 tonnes over a distance of 200,000 kilometers. This achievement represents a 25 percent reduction compared to its existing fully electric C40 and XC40 models. By electrifying its vehicles and focusing on sustainable practices, Volvo Cars is looking to make significant strides towards their goal of becoming a climate-neutral company by 2040.

As a fully electric car, the Volvo EX30 boasts zero tailpipe emissions, contributing to improved air quality. Recent research conducted by the University of Southern California highlights the positive impact of electric vehicles on air quality, indicating a decrease in emergency room visits due to asthma in areas with an increased adoption of electric cars.

However, Volvo believes that electrification alone is not sufficient to achieve the required reduction in carbon emissions. The entire lifecycle of a vehicle, including its design, development, production and transportation, presents opportunities for further greenhouse gas emission reductions. The Volvo EX30 looks to embody a more comprehensive approach to sustainability.

One key aspect of reducing the carbon footprint lies in the materials used during production. By designing a smaller car, less material is required, resulting in reduced emissions associated with the production of aluminium and steel. Furthermore, a significant portion of the aluminium and steel used in building the EX30 is recycled, further lessening its environmental impact.

Internally, the Volvo EX30 incorporates sustainable design principles. By optimising component design, the number of parts required is minimised, enhancing functionality while reducing waste. Additionally, the vehicle incorporates a higher percentage of recycled plastics than any previous Volvo model.

To achieve climate-neutrality, Volvo Cars says it is committed to reducing emissions not only in their own operations – but also throughout their supply chain. The factory responsible for manufacturing the Volvo EX30 will be powered by high levels of climate-neutral energy, including 100 percent climate-neutral electricity. Furthermore, 95 percent of Volvo's Tier 1 suppliers have committed to using 100 percent renewable energy in their production by 2025, aligning with Volvo's ambition to foster sustainability beyond its own operations.

Volvo Cars has also streamlined the production process for the EX30, achieving higher rates of material utilization in stamped body parts. In addition, the company utilizes blockchain technology to trace critical raw materials used in the production of battery packs, ensuring responsible sourcing of materials such as lithium, manganese, cobalt, graphite, and nickel.

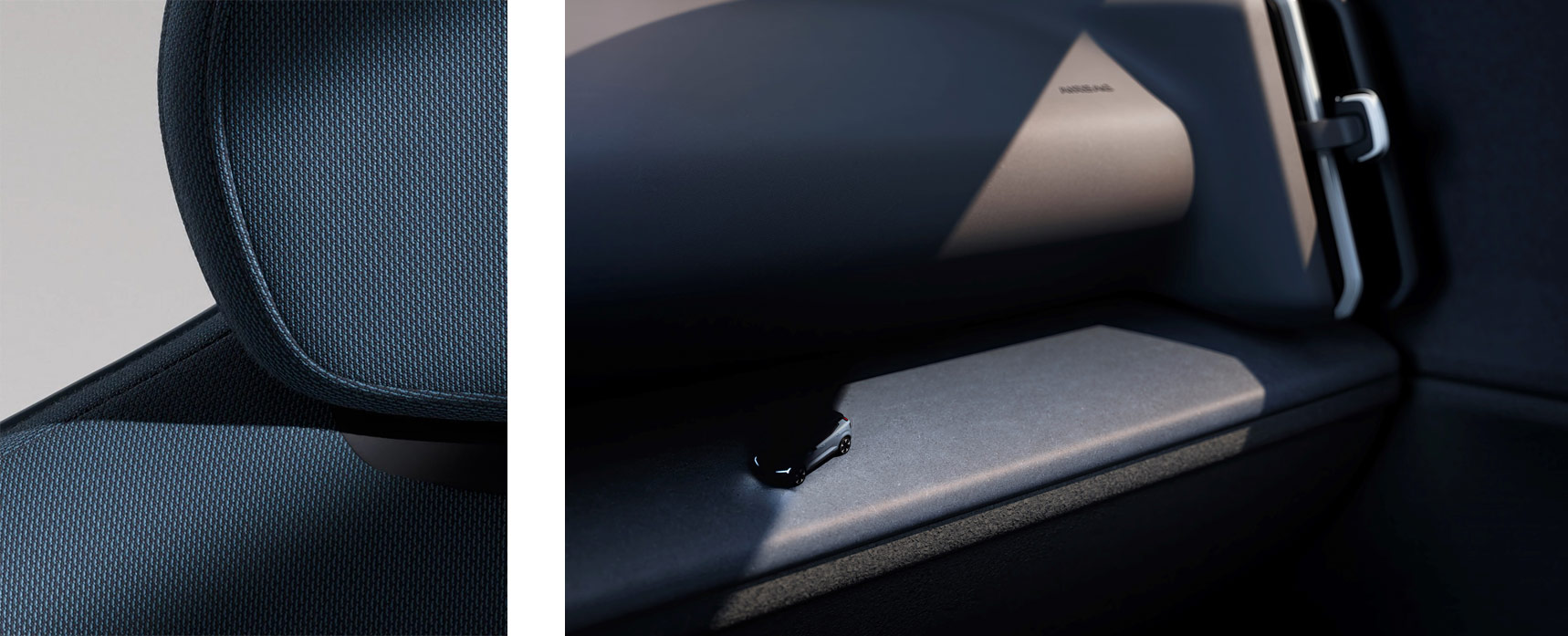

Inside the EX30, a wide array of recycled and renewable materials are used for seats, dashboard, and doors. Innovative materials such as denim, flax, and a wool-blend that contains approximately 70 percent recycled polyester contribute to the car's sustainable interior. Notably, the denim interior deco is created using fibres that would have otherwise been waste products in the denim recycling process, showcasing Volvo's commitment to finding smarter and more sustainable uses for materials.

With a cradle-to-gate CO2 impact estimated at 18 tonnes, the Volvo EX30 demonstrates a commitment to reducing the environmental impact throughout the vehicle's lifecycle. At the end of its life, the EX30 is designed to be recovered to 95 percent. The parts that cannot be recovered, can then be turned into energy.

Discussion about this post