Volkswagen Group Components has opened the Group’s first plant for recycling electric car batteries in Salzgitter.

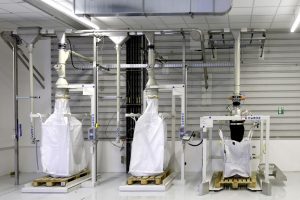

The goal of the company is the industrialised recovery of valuable raw materials such as lithium, nickel, manganese and cobalt in a closed loop together with aluminium, copper and plastics, achieving a recycling rate of more than 90% over the long term.

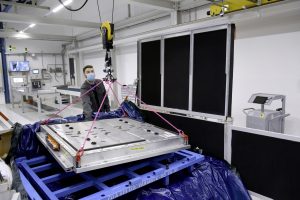

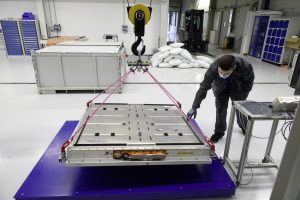

The unique feature of the Salzgitter plant is that it will only recycle batteries that can no longer be used for other purposes. Before the battery is recycled, an analysis determines whether the battery is still powerful enough to be given a second life in mobile energy storage systems such as the flexible rapid charging station or the mobile charging robot.

Since this is only the initial stage, the plant has been designed to initially recycle up to 3,600 battery systems per year, which is the equivalent to approximately 1,500 tonnes. In future, the system can be scaled up to handle larger quantities as the process is consistently optimised.

The innovative and CO2-saving recycling process does not require energy-intensive melting in a blast furnace. The used battery systems are delivered, deep discharged, and dismantled. The individual parts are ground into granules in the shredder and then dried. The separation and processing of the individual substances by hydrometallurgical processes, using water and chemical agents, is subsequently carried out by specialised partners.

Mark Möller, Head of the Business Unit Technical Development & E- Mobility has pointed out that this facility will help Volkswagen create a circular economy where nothing is wasted, and the materials retrieved will be used to build new batteries.

“From research, we know that recycled battery raw materials are just as efficient as new ones. In future, we intend to support our battery cell production with the material we recover,” he said. “Given that the demand for batteries and the corresponding raw materials will increase drastically, we can put every gram of recycled material to good use.”

Meanwhile, the factory in Dresden has begun series production of the fully electric ID.3. This makes it the second production site for the ID.3 and already the fourth site in the world producing Volkswagen models based on the Modular Electric Drive platform (MEB).

Also, Volkswagen has announced that the former “Center of Future Mobility” in the Saxon capital will become the “Home of the ID.” It will be offering customers, visitors and guests a holistic experience of the ID. Family, from initial advice and test drives, to production visits, co-constructing the ID.3 and modern event formats, up to the handover of electric vehicles.

Thomas Ulbrich, Member of the Board of Management for Electric Mobility at Volkswagen has explained that the company is heavily investing in its all-electric future in order to become a dominating force in the electric vehicle market.

“Volkswagen is continuing to pursue its electric offensive. In addition to new electric models, this also includes the transformation of the global production network,” he said. “At Dresden we are already converting the fourth Volkswagen site to the new ID. family and the MEB. At the same time, we are ramping up volume production in the Zwickau electric car plant and in our two Chinese MEB plants every week. In doing so we reaffirm our ambitions to take on a role as global leaders in electric mobility.”

Discussion about this post