Last updated on April 8th, 2020 at 07:57 pm

In February 2019, the Volkswagen Group launched its own Carbon Fund. The multinational automaker contributes €25 million annually into its fund for its twelve subsidiaries (such as Audi, Seat and VW). The Group's brands can then use it to finance their own climate protection projects – that aim to improve energy efficiency or otherwise save energy – anywhere in the world.

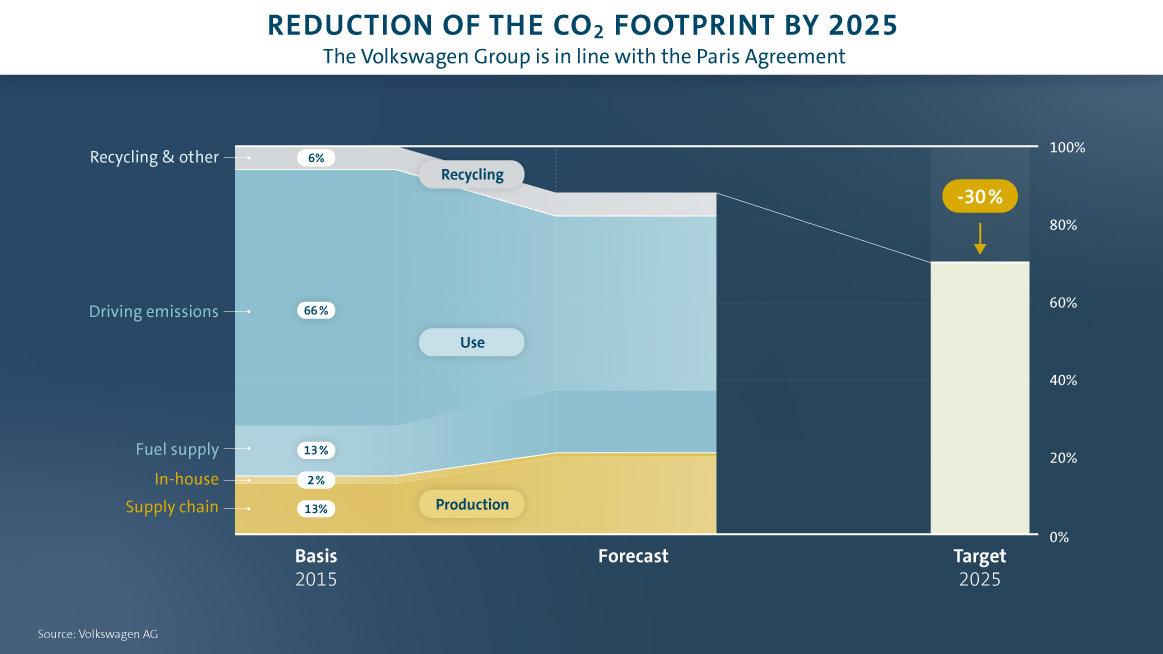

Additionally, these funds can be used to accelerate innovation, and strengthen new and existing business models. In just under ten months, more than 94 energy efficiency projects were successfully implemented; these will now be repeated until the 30% reduction of the Group's CO2 footprint is achieved – the aim is to reduce CO2 across the board: recycling accounts for 6%; driving emissions 66%; fuel supply 13%; in-house 2% and the supply chain 13%, which make up the company's carbon footprint.

Read next: Wandsworth wants to become the greenest inner London borough by 2030

Decarbonization requires the implementation of many individual projects. Here are some examples of the projects that took place in 2019:

- “LED Lighting” project: Across nine of the Group's production sites, a total of 33 measures were implemented to switch to more energy-saving lighting methods; as a result, this reduced 116,000 metric tons of annual CO2 production.

- “Refrigeration supply” project: In Kassel, existing refrigeration units were and are being replaced by more efficient separation circuit systems. To date, over 150 refrigeration units have been replaced. Better still, the heat needed in the cooling network also reduced by 23% – this equated for a total of 1,350 metric tons annually.

- “Various Infrastructure” project: In this project, new energy-efficient pumps were installed. Equally, with these works, building roofs were renovated and new cabinet cooling systems were installed. This project will save 2,000 tons annually.

- “Paint shop and dryer” project: A new load-dependent volume flow control system was installed at the Hanover site, which helped save 1,200 tons of CO2 annually. Further, the Group implemented other projects in conjunction with this one to further save 1,800 tons of CO2.

- “Washing Processes” project: Industrial washing machines were optimised at several locations across the Group – operating parameters such as pressure and volume flow, temperatures and standby times were optimally adjusted, too. This saves 2,900 metric tons of CO2 being emitted annually.

- “Other production processes” project: Modern temperature regulation technology was installed on three die casting machines, which helped reduce CO2 emissions by 2,500 metric tons annually.

Read next: EV popularity increases by 144% in 2019

For this year, the Volkswagen Group is looking at implementing over 100 new projects to help it meets its goal. It's great to see one of the biggest manufacturers in the world addressing climate change head-on.

Discussion about this post